Cylinder Liner Manufacturer: Elevating Quality and Performance in Diesel Engine Parts

In the dynamic world of diesel engines, the components that form these powerful machines are crucial to their overall efficiency, durability, and performance. One key component that significantly influences these factors is the cylinder liner. As a leading cylinder liner manufacturer, we understand the intricacies of creating parts that cater to the demands of modern diesel engines. This article delves into the importance of cylinder liners, their manufacturing process, and how they contribute to the overall success of diesel engine performance.

Understanding Cylinder Liners

A cylinder liner, also known as a cylinder sleeve, is a cylindrical part inserted into the engine block to house the piston. Its primary role is to provide a wear-resistant surface for the piston to operate within, thus ensuring efficient combustion and power generation. But why are cylinder liners so critical in the functioning of diesel engines?

- Protection Against Wear: Diesel engines operate under extreme conditions, including high temperatures and pressures. Cylinder liners protect the engine block from wear and tear.

- Improved Engine Longevity: By minimizing friction and wear, quality cylinder liners help extend the life of the engine.

- Enhanced Thermal Efficiency: Properly designed cylinder liners contribute to better heat dissipation, which is crucial for maintaining optimal engine temperatures.

- Piston Support: Cylinder liners provide a robust support system for the pistons, allowing for smoother operation and improved performance.

Types of Cylinder Liners

As a top-tier cylinder liner manufacturer, we produce various types of cylinder liners, each designed to meet specific engine requirements. Here are the main categories:

1. Wet Cylinder Liners

Wet cylinder liners are those that are in direct contact with the engine's coolant. This design helps improve cooling efficiency but requires precise manufacturing to avoid leaks.

2. Dry Cylinder Liners

Dry cylinder liners do not come into contact with coolant and are typically used in applications where weight is a concern. They are usually easier to replace compared to wet liners.

3. Integral Cylinder Liners

These liners are part of the engine block and cannot be removed separately. They are manufactured as a single piece with the block, ensuring stronger performance but limited replacement options.

The Cylinder Liner Manufacturing Process

The manufacturing of cylinder liners involves several stages, each critical to ensuring the final product meets industry standards and client expectations. Let’s explore this process in detail:

1. Material Selection

Choosing the right materials is essential. High-quality cast iron or steel alloys are typically used, as these materials provide the necessary strength, durability, and thermal conductivity.

2. Casting

The selected materials are melted and poured into molds to create the basic shape of the liners. This process must be executed with precision to avoid defects.

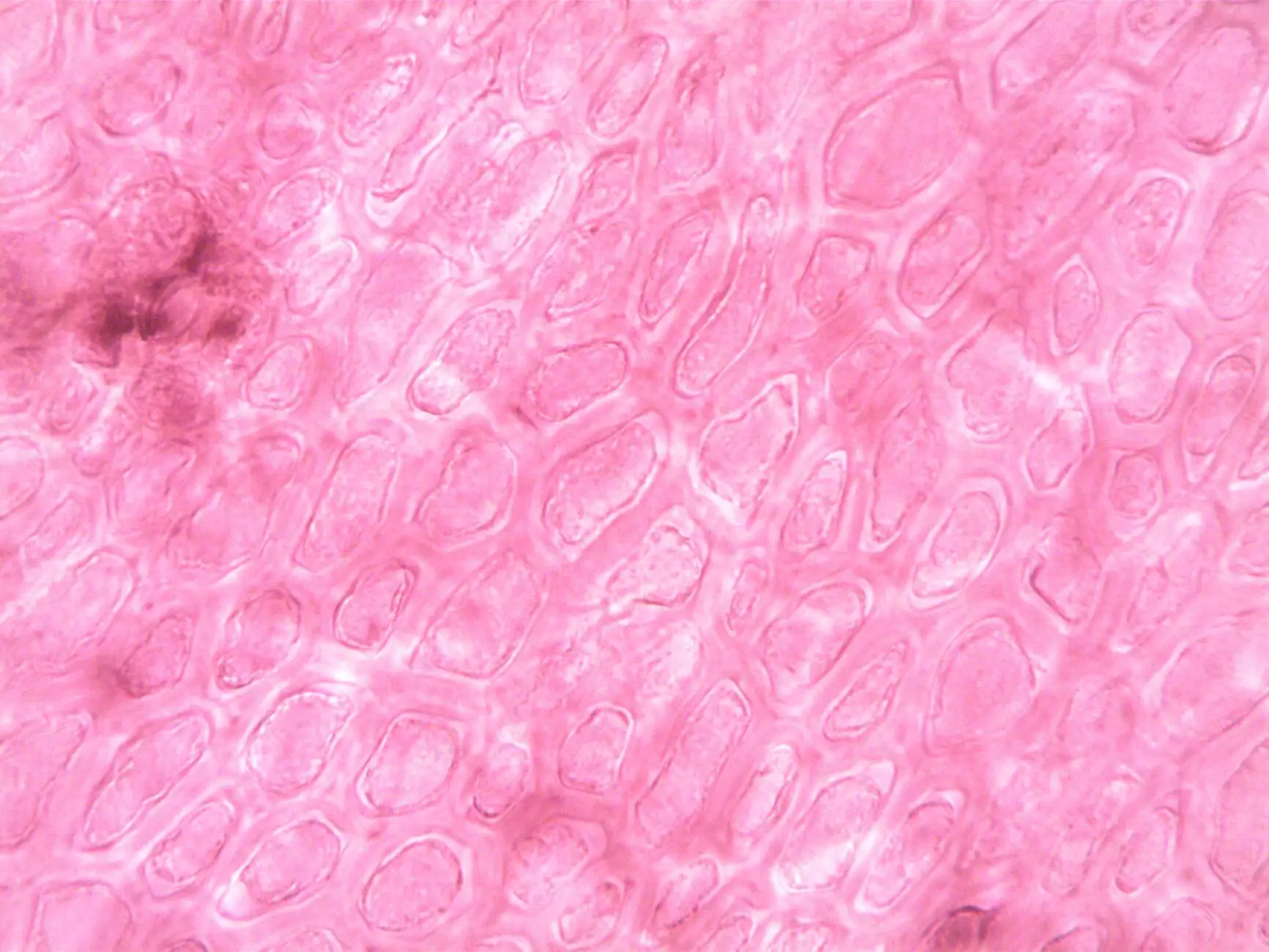

3. Machining

Once the casting is solidified, the liners undergo extensive machining to achieve the desired dimensions and tolerances. This includes boring and honing to create a smooth surface for the piston.

4. Surface Treatment

To enhance durability and reduce wear, the liners are often subjected to various surface treatments, such as hardening or coating, ensuring they can withstand the tough conditions of diesel engine operation.

5. Quality Assurance

Each cylinder liner undergoes rigorous quality checks to ensure it meets all specifications. This includes dimensional inspections, surface finish evaluations, and performance testing.

The Role of Cylinder Liners in Diesel Engines

The significance of cylinder liners in diesel engines cannot be overstated. They play a pivotal role in enhancing engine efficiency, performance, and reliability. Here are some of the key contributions:

1. Fuel Efficiency

Properly functioning cylinder liners reduce friction between the piston and liner, allowing the engine to operate more efficiently. This increased efficiency translates into better fuel economy.

2. Power Output

With less energy lost to friction, more power is transmitted from the fuel combustion to the crankshaft, resulting in higher power output and performance from the engine.

3. Emission Control

Better efficiency and performance lead to cleaner combustion, which means lower emissions. Many manufacturers are now focusing on developing cylinder liners that assist in meeting stringent environmental regulations.

Choosing the Right Cylinder Liner Manufacturer

For businesses looking to procure cylinder liners, selecting a reputable cylinder liner manufacturer is crucial. Here are some tips on what to consider:

- Experience and Reputation: Look for manufacturers with a proven track record in the industry. Reputation can greatly impact the quality of their products.

- Quality Assurance: Ensure the manufacturer adheres to strict quality control processes. Certifications such as ISO can provide peace of mind.

- Technology and Innovation: The best manufacturers invest in advanced technologies to enhance their production processes and develop high-performance cylinder liners.

- Customer Support: A responsive customer service team can make a significant difference in addressing your concerns and ensuring you receive the products you need.

Client Diesel: Your Trusted Cylinder Liner Manufacturer

At client-diesel.com, we pride ourselves on being a leading cylinder liner manufacturer tailored for the diesel engine market. Our commitment to quality, innovation, and customer satisfaction sets us apart from the competition. Here’s what makes us a top choice:

1. High-Quality Products

Every cylinder liner produced in our facility undergoes rigorous quality inspections, ensuring that only the highest quality products reach our clients.

2. Expertise and Innovation

With years of experience, our team of experts understands the complexities of diesel engines and continually innovates to improve our product offerings.

3. Competitive Pricing

We offer competitive pricing without compromising on quality, making our cylinder liners an excellent investment for businesses in the diesel engine sector.

4. Custom Solutions

Understanding that different applications require unique solutions, we offer customizable options to meet specific client needs in their engine applications.

Conclusion

The role of a cylinder liner manufacturer in the performance and longevity of diesel engines is essential. By investing in high-quality cylinder liners, engine manufacturers and users can improve fuel efficiency, enhance power output, and meet emission regulations effectively. As a leading provider, client-diesel.com is dedicated to delivering the best products to our clients, ensuring they have the components necessary for success in the competitive diesel engine market.

For more information on our cylinder liners and how we can help boost your engine’s performance, visit our website at client-diesel.com.