Elevating Manufacturing Excellence: The Comprehensive Guide to Metal Fabricators & the Leading China CNC Lathe Machining Parts Factory

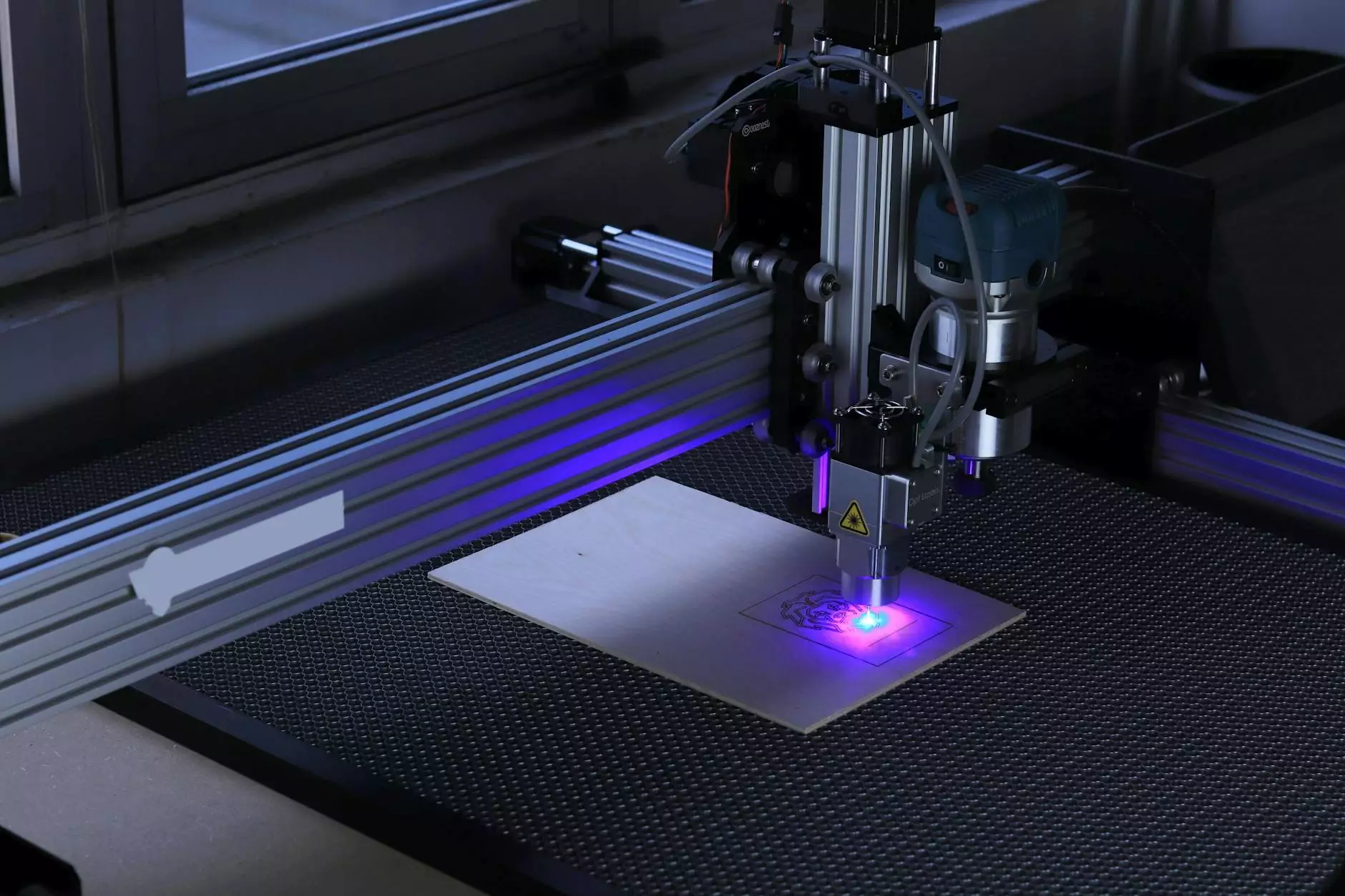

In today’s thriving industrial landscape, precision manufacturing plays a pivotal role in driving innovation and ensuring the highest standards of quality across various sectors such as automotive, aerospace, electronics, and machinery. At the heart of this technological evolution are professional metal fabricators who specialize in crafting complex, durable, and high-precision components. Among these, DeepMould.net stands out as a premier metal fabricator offering superior China CNC lathe machining parts, which are essential in modern manufacturing processes.

Why Metal Fabrication is Critical in Modern Industry

Metal fabrication involves transforming raw metal materials into functional components through various cutting, machining, welding, and assembling techniques. The significance of metal fabricators in industry can be summarized through several key points:

- Customization & Flexibility: Metal fabricators provide tailored solutions that meet specific client requirements, ensuring high compatibility with end-use applications.

- High Precision: Modern fabrication techniques, such as CNC machining, allow for extremely tight tolerances, critical for industry standards.

- Scalability & Efficiency: Whether small batches or mass production, professional fabricators optimize their processes to maximize output without compromising quality.

- Innovation & Complexity Handling: Advanced fabrication facilities can produce intricate designs not feasible through traditional methods.

DeepMould.net: A Top-Tier Metal Fabricator Leading the Market

DeepMould.net has cemented its reputation as a reliable and innovative metal fabricator, specializing in high-precision CNC lathe machining parts sourced directly from China. Our manufacturing plant is equipped with cutting-edge machinery and a skilled team dedicated to delivering excellence across every project.

Our Capabilities in Metal Fabrication

At DeepMould.net, we offer a comprehensive suite of services tailored to meet diverse industry demands, including:

- CNC Turning & Milling: Precision machining of complex geometries with tolerances as tight as ±0.01mm.

- Sheet Metal Fabrication: Cutting, bending, and assembling for lightweight and durable components.

- Welding & Assembly: High-quality welding techniques ensuring strong, reliable joints for various metals

- Surface Treatment & Finishing: Processes like polishing, anodizing, and coating to enhance durability and aesthetics.

Why Choose DeepMould.net as Your China CNC Lathe Machining Parts Factory

Our commitment to excellence and customer satisfaction makes us the ideal partner for your manufacturing needs. Here are some reasons why:

- Unmatched Quality Control: Our stringent QC processes ensure each part meets international standards.

- Competitive Pricing: Leveraging Chinese manufacturing strengths, we provide premium parts at highly competitive rates.

- Advanced Technology: State-of-the-art CNC machines and software enable us to produce complex, high-precision components consistently.

- Fast Turnaround & Delivery: We understand project timelines and prioritize timely deliveries without compromising quality.

- Customized Service & OEM Capabilities: Our team collaborates closely with clients, offering tailored solutions and OEM services.

Advantages of Partnering with a China CNC Lathe Machining Parts Factory

Opting for a reputable China CNC lathe machining parts factory offers several significant benefits:

- Cost Efficiency: Lower labor and manufacturing costs allow for high-quality parts at reduced prices.

- High Production Capacity: Chinese factories can scale up production rapidly to fulfill large orders.

- Technological Expertise: Continuous investments in machinery and skilled workforce ensure precision and innovation.

- Supply Chain Integration: Strategic positioning and logistics networks facilitate smooth global distribution.

Critical Factors in Selecting the Right CNC Machining Partner

Choosing the right China CNC lathe machining parts factory is crucial for project success. Key considerations include:

- Manufacturing Certifications: ISO 9001, ISO 13485, and other quality assurance standards indicate reliability.

- Technical Capabilities: Compatibility with your specific design requirements and complex geometries.

- Material Expertise: Ability to work with various metals like aluminum, steel, brass, and titanium.

- Lead Time & Flexibility: Quick turnaround and adaptability to design modifications.

- Customer Service & Communication: Clear, effective communication channels promote smooth project execution.

Industry Applications of Precision Machined Components from China CNC Lathe Machining Parts Factory

The precision CNC machined components from DeepMould.net integrate into numerous high-demand industries, including:

Automotive Industry

Manufacturing engine parts, transmission components, and custom brackets with stringent tolerances to ensure safety and performance.

Aerospace Sector

Producing high-strength, lightweight components critical for aircraft performance, including structural parts and hydraulic system components.

Electronics & Electrical

Creating precise enclosures, connectors, and intricate circuit components that demand exact measurements.

Medical Devices

Supplying biocompatible, high-precision parts used in surgical instruments and implantable devices.

Industrial Machinery

Fabrication of durable, reliable parts for automation, robotics, and heavy-duty equipment.

Innovations & Technological Trends Shaping China CNC Machining Industry

The industry of CNC machining is continuously evolving with advances that drive better precision, efficiency, and sustainability:

- Automation & AI Integration: Enhancing quality control and reducing human error.

- Advanced Materials: Growing use of composites and specialized alloys requiring sophisticated machining techniques.

- Smart Manufacturing: IoT-enabled factories that monitor, optimize, and manage production remotely.

- Sustainable Practices: Implementing eco-friendly processes, waste reduction, and energy-efficient operations.

Conclusion: Why DeepMould.net Is Your Trusted China CNC Lathe Machining Parts Factory

In an increasingly competitive global market, selecting a reliable and high-quality manufacturer for China CNC lathe machining parts is essential. DeepMould.net offers unmatched expertise, advanced technology, and strict quality controls, delivering components that meet and exceed industry standards. Our dedication to customization, cost-efficiency, and superior service ensures that your manufacturing projects are successful, scalable, and future-ready.

Partner with us today and experience how our comprehensive metal fabrication solutions can elevate your business and bring your innovative ideas to life with precision and reliability. With DeepMould.net, your success is our priority.